Durable ADS self-cleaning filter for demanding screening

ADrecipe is a browser-based software tool that operates above the process control system, requiring no additional installation on any workstation connected to the factory network.

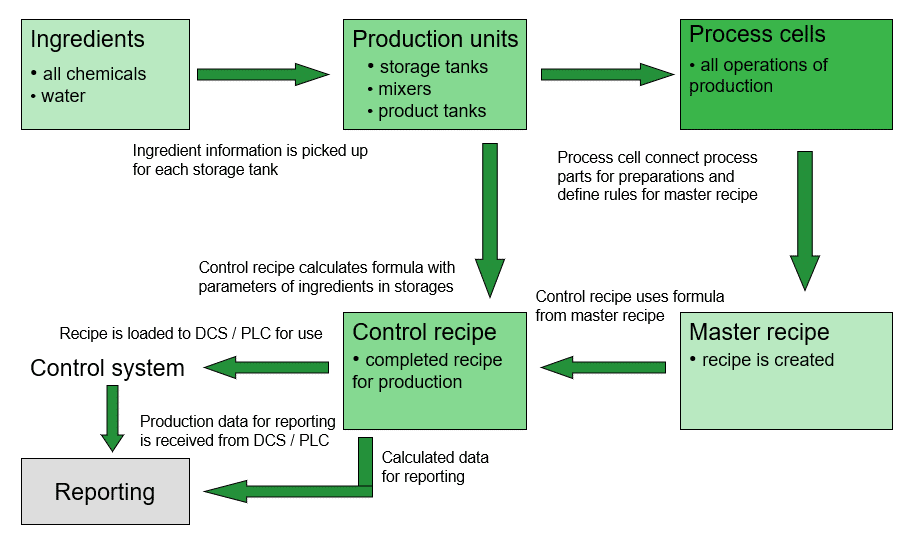

ADrecipe follows ISA-88 batch standard.

OPERATING PRINCIPLES MAIN FUNCTIONS:

Recipe Management

- Create and calculate recipes.

- Load recipes into the control system for production.

- Supports both batch and continuous production processes.

- Recipes are created in Master Recipe level and published to Control Recipe level for production. Control Recipe is loaded to the process control system. The number of stored recipes is not limited.

Reporting

- Monitor production in real-time.

- Store all production data in a database.

- Generate detailed reports on production and consumption, available for years.

- Production Report consists of batches and continuous production. Detailed Batch and Continuous Reports are opened from Production Report

Supporting Functions

- Ingredient Management

- Ingredients with properties are stored in Ingredient Library.

- Production Unit Management

- Storage tanks, utility lines , mixers and production tanks are all Production Units. Ingredients are located in Production Units. Content of a Production Unit can be easily changed.

- Process Cell Management

- Structure of process is created in Process Cell. Process Cell gives limits for recipe. Batch and Continuous preparations are available.

YOUR BENEFITS WITH ADRECIPE

Efficiency and Accuracy:

Automated Recipe Management: Reduces manual errors and ensures consistency in production. Real-time Monitoring: Allows for immediate adjustments, minimizing downtime and waste.

Data-Driven Decisions:

Comprehensive Reporting: Provides detailed insights into production and consumption, helping to identify trends and optimize processes. Historical Data Access: Enables long-term analysis and strategic planning based on years of stored data.

Scalability and Flexibility:

Browser-Based Access: Can be used on any workstation connected to the factory network without additional installations. Support for Various Production Types: Accommodates both batch and continuous processes, making it versatile for different manufacturing needs.

Enhanced Traceability and Compliance:

Ingredient and Production Unit Management: Ensures all components are tracked and managed efficiently. Process Cell Management: Helps maintain compliance with industry standards and regulations.

Cost Savings:

Reduced Waste: By optimizing recipes and monitoring production in real-time, the system helps minimize material waste. Lower IT Overhead: Being browser-based, it reduces the need for extensive IT infrastructure and maintenance.