GENERAL:

A strainer in a coating or sizing circulation system serves a crucial role in keeping the coating color and sizing starch quality good and protecting equipment by filtering out debris and paper shreds which would end up in coating circulation and machine supply tank. The strainer is typically used in coating return line and during coating brakes to keep the system clean.

Adpap Oy Ltd’s solution for this purpose is ADT Strainer. ADT Strainer is a coarse screen which is designed for efficiently removing paper shreds and other possible particles from entering the coating color circulation.

The ADT Strainer meets current standards and complies with the EN machinery directive and the unit is CE labelled.

OPERATING PRINCIPLE:

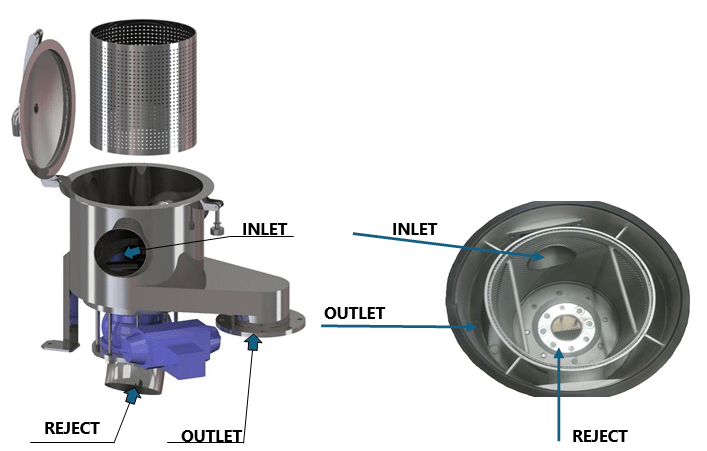

The ADT Strainer is typically installed on the machine level under the coating or sizing head. During normal operation, the fluid enters the strainer housing and flows through a filter basket with 4 – 8 mm perforations. This filter basket traps solid particles and contaminants. As the fluid passes through the strainer, debris accumulates inside the filter element.

During the brakes strainer performs cleaning process to remove the accumulated debris. The reject valve opens, and the reject is washed out to the drain with the help of flushing system. After the cleaning cycle, the strainer returns to its normal filtration mode, ready to trap new solid particles.

ADT STRAINER CONSTRUCTION:

ADT-Strainer is manufactured from stainless steel AISI 316, which provides good tolerance against mechanical wearing and chemicals. The hinged cover allows for easy access, making manual inspections and maintenance tasks more straightforward.

Automatic inlet and outlet valves, along with an automatic flushing system, ensure the strainer operates efficiently with minimal manual operation.

ADT STRAINER CAPACITY:

Due to the modular design of ADT Strainer one unit can be designed over the wide range of air containing flows. In principle we can remove air from solutions from 100 l/min up to 1500 l/min in one unit. The amount of cyclones in unit is always carefully adjusted based on the volume flow and solution properties.

YOUR BENEFITS WITH ADT STRAINER:

ADT Strainer removes efficiently particles from coating colors and surface sizing return flow ensuring a smooth and uniform application

ADT Strainer can be used for example with coating color and surface sizing.

ADT Strainer is easy to operate, has no moving parts and requires only a minimum amount of service from operating personnel.

Only high-quality materials are used in filter manufacturing, which enables good functioning and long lifetime even in challenging environment.

To make it easy for you, Adpap Ltd. can offer operation assistance and optimization and complete spare part packages for ADT Strainer units.