GENERAL:

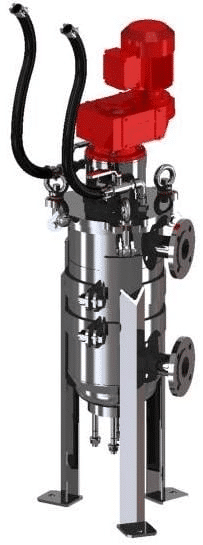

The ADS self-cleaning filter is a robust and compact automatic self-cleaning filter designed for demanding screening applications. Its state-of-the-art design makes it suitable for many industrial screening purposes where operational reliability is essential. It is used for applications such as coating colors, starch, pigments, and lime milk, as well as several other challenging screening tasks.

The ADS filter meets current standards, complies with the EN machinery directive, and is CE labelled.

ADS SELF-CLEANING FILTER CONSTRUCTION:

The ADS self-cleaning filter is manufactured using only high-quality materials. All wetted parts are made of stainless steel (EN 1.4404). The drive shaft of the strainer is sealed to the cover with either a cord seal or a mechanical seal, depending on the specific requirements. The design allows for a maximum operating pressure of 10 bar.

There are two excellent options for the screening drum design: wedge wire or perforated models. The choice of drum type is based on customer needs. The ADS self-cleaning filter scraper blades are spring-loaded and made of synthetic material, enabling efficient yet gentle scraping of particles across the entire screen drum surface.

The scraping blade shaft assembly and the reject space agitator at the bottom of the screen are rotated by a small gear motor.

The screen cover is hinged to the vessel and secured with quick-fastening eye bolts, allowing for easy opening without any special tools.

OPERATING PRINCIPLE:

The ADS self-cleaning filter operates on an inside-out principle. Material is fed into the screen through the upper inlet. Particles smaller than the slot size flow through the screen drum, and the accept is led out from the lower connection on the side of the vessel. This connection is located either directly below the feeding connection or on the opposite side.

A key features

Particles that do not pass through the screen drum are removed from the drum’s inner surface by scraping blades and sink to the reject space at the lower part of the screen. The reject is intermittently removed from the filter bottom. The opening and closing of the outlet valve are controlled by an automatic control system. Typically, the reject valve opens for only a few seconds, during which the filter remains in operation without disturbing the process, minimizing liquid loss due to cleaning. An additional agitator in the reject space at the bottom of the screen keeps the accumulated reject material moving, preventing sedimentation and enabling smooth removal of the reject.

A key feature for the good functioning of the self-cleaning filter is the continuous two-way scraping of the screen’s inner surface. The ADS filter has two spring-loaded scraping blades made of synthetic material that remove impurities from the drum surface and maintain the pressure difference at a sufficient level.

Additional features of the ADS filter include an air removal connection and a flushing connection on the screen top cover. If free air is present in the liquid and may cause problems further in the process, it can be easily removed through the air removal connection on the ADS filter cover. The flushing nozzle can be used to improve washing efficiency by introducing water through the nozzle to the contact point of the screen drum and scraping blades while scraping the screen drum’s inner surface.

ADS SELF-CLEANINGFILTER CAPACITY:

Adpap Ltd. offers standard filter sizes for various capacities, ranging from 50 liters per minute (lpm) up to 3000 lpm per filter unit. The screen drum slot size can vary from 75 µm to 800 µm. The appropriate filter type and filtration slot size are always optimized based on customer needs.

YOUR BENEFITS WITH ADS SELF-CLEANING FILTER:

Comprehensive Solutions:

Adpap Ltd. can deliver single automatic self-cleaning filters, multiple filters, or complete ready-made screening processes with integrated automation systems according to your needs

Durability:

High-quality materials are used in filter manufacturing, ensuring good functionality and a long lifespan even in challenging environments.

Ease of use:

The ADS self-cleaning filter is automatic and continuous. Its operation is easy and requires minimal effort from operating personnel.

Efficiency:

With the automatic self-cleaning filter, reject removal occurs during operation without interrupting the actual filtration process. This means continuous filtering and minimal raw material losses.

Support and spare parts:

Adpap Ltd. offers operation assistance, filter optimization, and complete spare part packages for ADS self-cleaning filters.